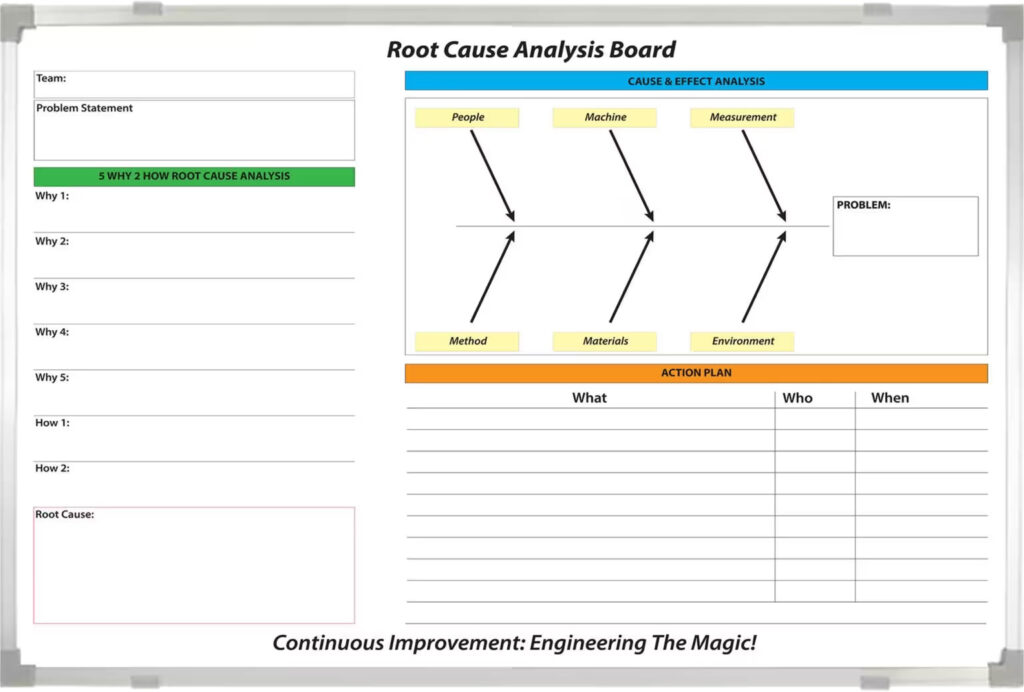

A Lean fishbone diagram, also known as a Lean cause-and-effect diagram or Lean Ishikawa diagram, is a problem-solving tool used in Lean methodology to identify and analyze the root causes of a problem. It’s based on the original Ishikawa fishbone diagram, but it’s adapted to the Lean principles of waste reduction and continuous improvement. Here’s how to properly use a Lean fishbone diagram:

- Define the problem: Start by clearly defining the problem or issue you want to address. Be specific and concise in your problem statement. This will serve as the “head” of the fishbone diagram.

- Assemble a cross-functional team: Lean encourages collaboration across different functions and departments. Gather a diverse group of team members who have knowledge and expertise related to the problem.

- Identify major categories (bones): Create a horizontal line (the “spine” of the fishbone) extending from the problem statement. At the end of this line, draw several diagonal lines (the “bones”) radiating out like the skeleton of a fish. Each bone represents a major category or factor that may contribute to the problem. These categories are typically based on the 7 Wastes (Muda) of Lean manufacturing: Transportation, Inventory, Motion, Waiting, Overproduction, Overprocessing, and Defects. However, you can adapt the categories to fit your specific problem.

- Brainstorm potential causes: With the major categories in place, have your team brainstorm potential causes or factors within each category that could be contributing to the problem. Encourage open and honest discussion, and use tools like the 5 Whys technique to delve deeper into the root causes.

- Document causes on the diagram: Write down the identified causes or factors on the appropriate branches (bones) of the fishbone diagram. Use clear and concise language. This process helps visualize the cause-and-effect relationships.

- Analyze and prioritize causes: Review the causes you’ve identified and consider their impact on the problem. Prioritize the most significant and influential causes that should be addressed first.

- Identify solutions: For each prioritized cause, brainstorm potential solutions or countermeasures. Encourage creativity and input from team members.

- Implement improvements: Once you’ve identified solutions, create an action plan for implementing them. Assign responsibilities and set deadlines to ensure accountability.

- Monitor and measure: After implementing the improvements, monitor the results and measure their impact on the problem. Continuously track progress and make further adjustments if necessary.

- Reflect and adapt: Lean is a continuous improvement process. Regularly review the effectiveness of your solutions and make adjustments as needed. Consider using PDCA (Plan-Do-Check-Act) or other Lean improvement cycles to refine your approach.

Remember that the goal of a Lean fishbone diagram is to identify and eliminate waste and inefficiencies in processes while addressing the root causes of problems. It’s a valuable tool for problem-solving and continuous improvement in Lean environments.