Maintaining a functioning supply chain is no small task. From planning production schedules to coordinating with suppliers, keeping up streamlined communication across teams can be challenging. Fortunately, the use of physical tools, such as custom-printed whiteboards, has proven to be a reliable method for improving processes and maintaining transparency in complex operations.

Whiteboards Enhance Collaborative Planning

One of the primary ways whiteboards support supply chain management is by bringing teams together for planning and problem-solving. Supply chain operations typically encompass various departments, including procurement, production, inventory control, and distribution. Seamless collaboration between these different functions is essential to avoid delays, inefficiencies, and miscommunications.

Whiteboards serve as a central hub for aligning a team’s efforts. Unlike digital tools, which can feel impersonal or complex to some team members, whiteboards provide a hands-on experience. During meetings, teams can outline production targets, create delivery schedules, and track milestones in a way that is visible to everyone. This visual approach fosters mutual understanding and accountability, especially when multiple stakeholders are involved.

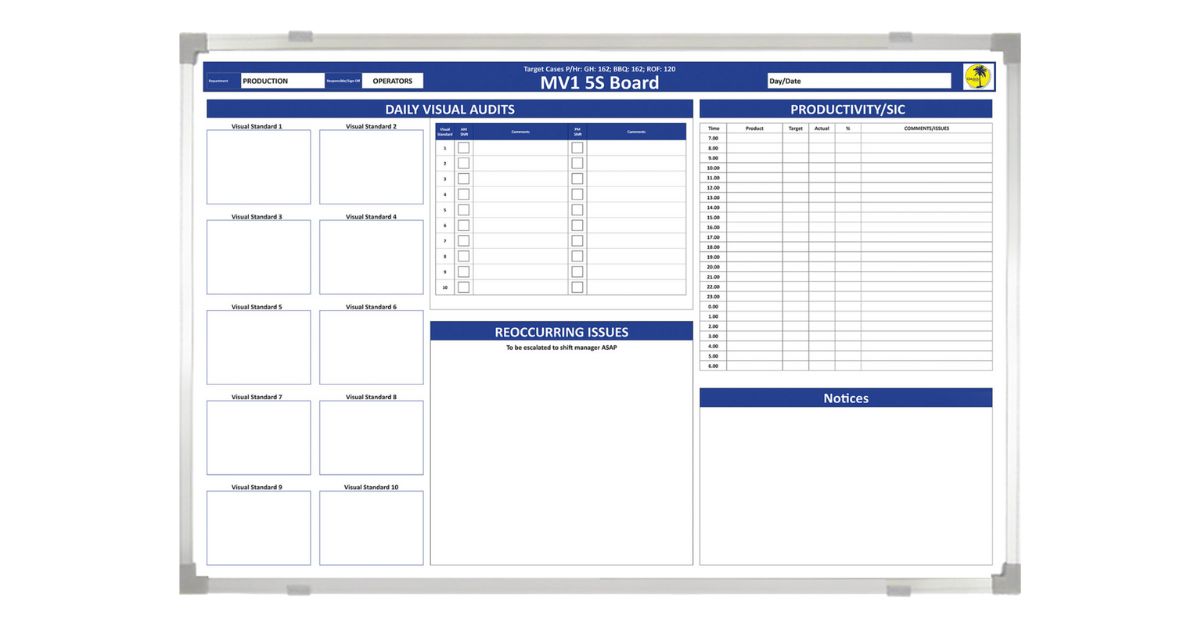

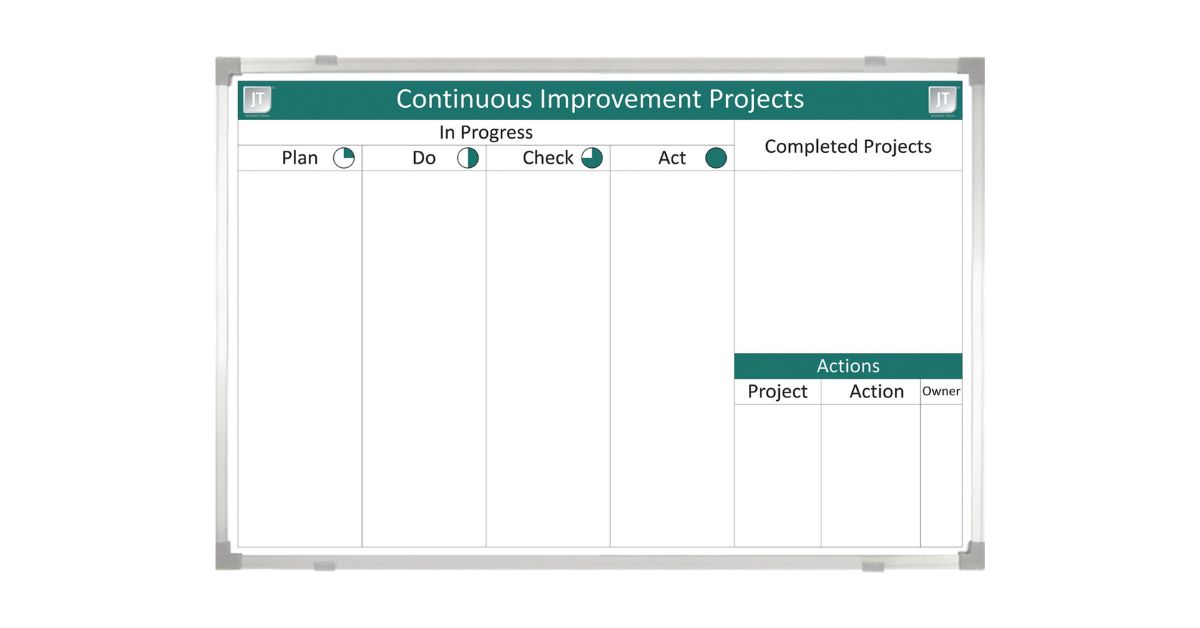

For example, whiteboards can be customized to display Kanban workflows, which are widely used in supply chain environments. With this visual representation, everyone can see real-time progress and review bottlenecks directly during meetings. This shared visibility ensures no one is in the dark when priorities shift or issues arise.

Customized boards also allow organizations to tailor layouts to meet specific needs. From simple gridlines for organizing supplier schedules to complex diagrams for planning routes, whiteboards offer endless possibilities for enabling effective collaboration across departments.

Visualization Drives Supply Chain Clarity

Visualizing goals and metrics is essential to ensuring efficiency in supply chain processes. Whiteboards excel at providing clarity through their visual representation, which allows details to stand out in a straightforward manner. Charts, graphs, and progress indicators written on whiteboards make sure that everyone understands the overall context of what is being tracked and who is accountable for particular tasks.

When it comes to performance management, for example, supply chain managers often track key performance indicators, such as on-time delivery rates or inventory turnover ratios. These metrics can be updated daily or weekly on whiteboards, adding transparency and allowing the entire supply chain team to see which areas are performing well and which need attention.

Likewise, lean manufacturing whiteboards offer a straightforward way to visualize workflows, eliminate redundant steps, and boost overall efficiency. Their ability to display critical details in one place keeps daily operations streamlined, even in high-pressure situations.

Another advantage of whiteboards is their flexibility. Digital dashboards often require technical expertise or lengthy setups, whereas updates to whiteboards can happen the moment something changes. Adding reminders, adjusting figures, and assigning tasks can be done in seconds, eliminating confusion within the team.

Real-Time Decision-Making Support

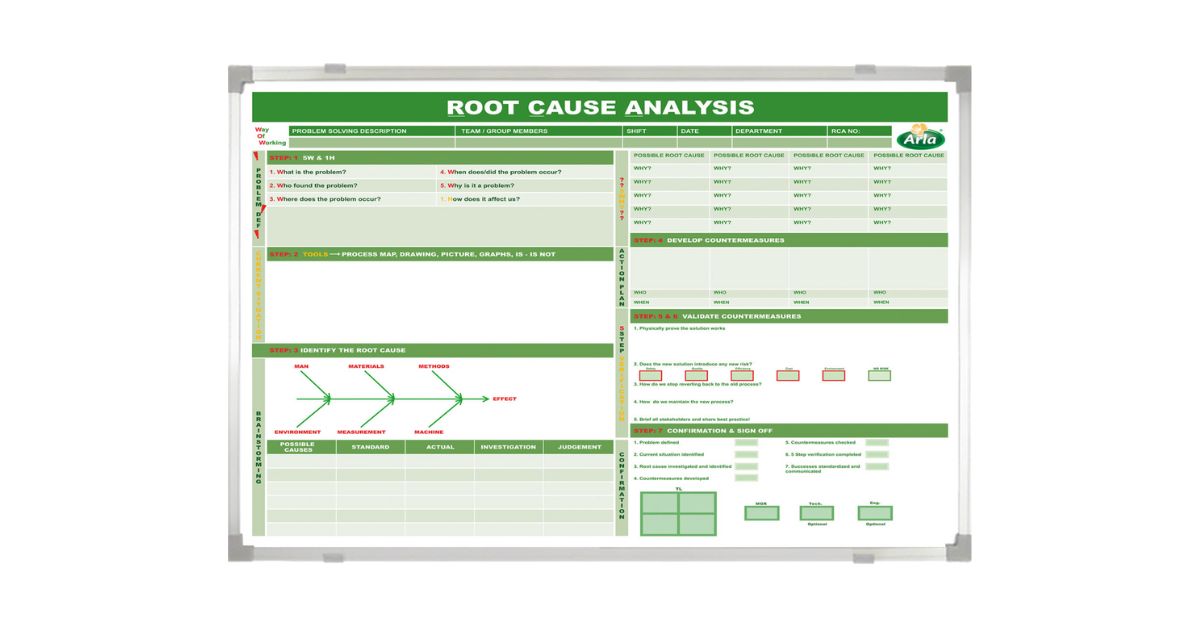

Supply chains are dynamic systems that are prone to constant fluctuations. Sudden delays, changes in demand, or supplier disruptions can impact processes if not handled in real time. Whiteboards play a crucial role in facilitating rapid, effective decision-making during unpredictable scenarios.

Their visibility makes them the ideal tools for hosting impromptu discussions. By gathering in front of a whiteboard, teams can map challenges, evaluate options, and determine next steps. Real-time brainstorming is especially efficient when everyone can see the situation visually.

For example, a materials shortage may require revising production timelines or adjusting supplier deliveries. By simply modifying the details on the supply chain whiteboard, managers and team members can quickly adapt plans and ensure operations continue without major disruptions.

Additionally, whiteboards aid in communication during shift handovers. Important updates or action points can be documented before the next team takes over, reducing misunderstandings and ensuring continuity across operations. This real-time adaptability strengthens the overall responsiveness of supply chains.

Accountability for Teams and Processes

Another meaningful way that whiteboards impact supply chain management is by holding teams accountable. Assigning and tracking responsibilities becomes more transparent when expectations are laid out within a shared work area. Both individual contributors and management teams benefit from knowing who is doing what and by when.

For instance, whiteboards might be sectioned off into team-specific priorities, with deadlines prominently displayed for tasks like inventory stocking, quality inspections, or shipping. Seeing responsibilities laid out publicly promotes accountability, encouraging team members to take ownership of their work.

Furthermore, whiteboards create an environment where updates are communicated more openly. By updating boards as tasks are completed, teams prevent misunderstandings or delays from missed progress updates. Clear accountability also helps management identify performance issues and determine when additional resources are needed to keep operations running smoothly.

Customizability enhances the accountability factor. Managers can design boards that highlight touchpoints critical to their industry or team structure. Labels, color markers, and divider grids can be implemented to designate areas for different priorities.

Cost-Efficiency and Scalability

While companies increasingly adopt digital tools in supply chain management, whiteboards remain a cost-effective solution for both small- and large-scale operations. Their affordability and ease of use make them an attractive option for businesses seeking quick improvements without dedicating significant budgets to IT platforms.

Small manufacturers or logistics businesses may not have the resources to invest in high-end visualization software, yet they still face complex supply chains. Whiteboards allow these organizations to achieve transparency and visualization without incurring excessive costs. Using such tools provides immediate functional benefits that scale easily with team sizes.

Even for larger corporations, whiteboards serve as a reliable supplement to digital systems. When integrated into daily workflows, whiteboards provide an accessible secondary layer of planning, which is particularly helpful for team members who prefer visual aids in physical spaces.

This practicality is the reason whiteboards remain a consistent solution across diverse industries that depend on smooth supply chain operations, including manufacturing, retail, and healthcare logistics.

Team Engagement

People are always at the core of efficient supply chains. Whiteboards facilitate team engagement through their interactive and manual format. Unlike passive tools that feel disconnected, whiteboards actively invite participation, with each team member contributing their ideas, plans, or updates directly.

This sense of involvement fosters stronger buy-in from team members, resulting in increased motivation. Supply chain operations benefit immensely when everyone feels aligned, connected, and invested in outcomes. By utilizing whiteboards during team meetings or day-to-day planning, businesses encourage collaboration where it matters most.

Creating a strong culture of participation ultimately leads to greater productivity throughout the organization. Engaged employees are far more willing to take ownership of issues, contribute innovative ideas, and help optimize procedures efficiently. With whiteboards at the centerpiece of such practices, improving engagement and morale becomes achievable.

Achieving Supply Chain Excellence With Whiteboards

From delivering visibility and collaborative potential to fostering accountability and boosting engagement, whiteboards have become a foundational tool for supply chain management. Their customizable designs and cost-effective applications allow them to adapt to various challenges that supply chain teams face daily.

Whether your organization manages simple distribution networks or highly complex systems, whiteboards remain a reliable resource for coordinating, planning, and executing tasks with clarity. Understanding how whiteboards support supply chain management and implementing them in your supply chain strategy can transform not only how your team works but also how efficiently your operations function.