Effective maintenance scheduling forms the backbone of operational efficiency across industries. Whether managing equipment servicing in manufacturing facilities or organizing routine inspections in healthcare environments, the ability to visualize and adjust maintenance schedules directly impacts productivity and safety outcomes.

Traditional scheduling methods often fall short when dealing with the dynamic nature of maintenance work. Paper schedules become outdated quickly, digital systems may lack visual clarity, and communication gaps can lead to missed maintenance windows or conflicting assignments. This creates a need for scheduling solutions that combine visual accessibility with the flexibility to accommodate last-minute changes and priority adjustments.

Scheduling maintenance with magnetic dry-erase boards offers a practical approach that addresses these common challenges. These boards provide maintenance teams with immediately visible, easily modifiable systems for tracking scheduled work, resource allocation, and completion status. The magnetic functionality adds another layer of organization, allowing teams to use color-coded magnets, movable task cards, or magnetic accessories to enhance their scheduling systems.

Visual Organization for Complex Schedules

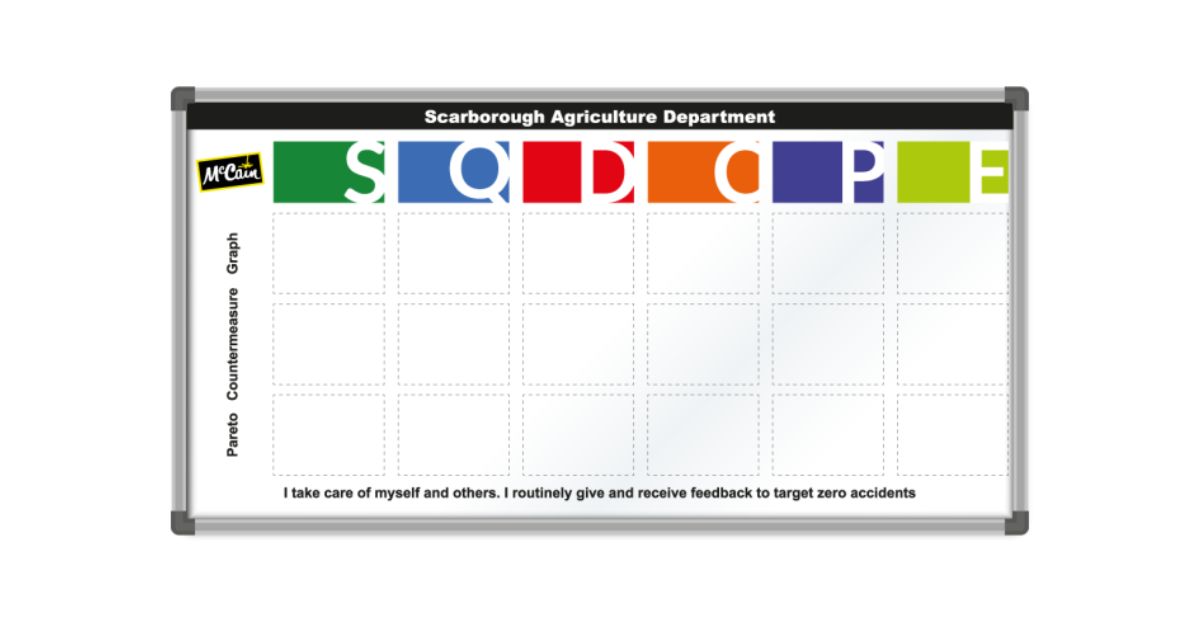

Maintenance departments typically juggle multiple types of work orders simultaneously. Preventive maintenance tasks are performed on predetermined schedules, whereas reactive maintenance occurs unpredictably throughout the day. Emergency repairs demand immediate attention and often disrupt carefully planned schedules. Managing this complexity requires a scheduling system that can accommodate various priority levels and time frames within a single, coherent view.

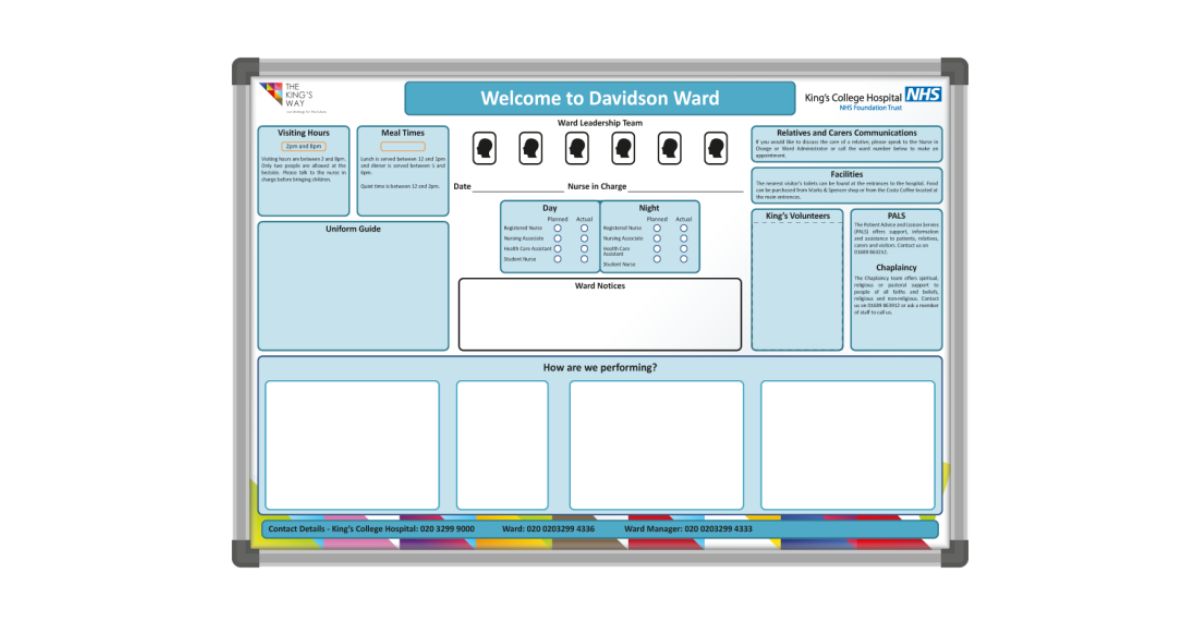

Magnetic dry-erase boards excel in this environment because they allow maintenance coordinators to create distinct sections for different types of work. Teams can designate specific areas of the board for daily tasks, weekly inspections, monthly overhauls, and emergency work. The magnetic surface enables the use of moveable elements that can shift between sections as priorities change throughout the day.

The visual nature of these boards means that entire maintenance teams can quickly assess workload distribution at a glance. Supervisors can identify potential scheduling conflicts before they become problems, while technicians can see their assigned tasks without accessing computer systems or searching through paperwork. This immediate visual feedback helps teams maintain awareness of both individual responsibilities and overall departmental workflow.

Flexibility in Real-Time Adjustments

Maintenance work rarely proceeds exactly as planned. Equipment failures can bump scheduled tasks to accommodate urgent repairs. Parts delays might postpone planned maintenance until inventory arrives. Weather conditions can affect outdoor maintenance activities. These variables require scheduling systems that adapt quickly without losing track of rescheduled work.

The erasable surface of these boards makes real-time adjustments straightforward. Maintenance coordinators can modify schedules instantly as conditions change, using different colored markers to indicate various types of work or priority levels. When combined with magnetic elements, teams can physically move task indicators around the board to reflect new scheduling realities.

This flexibility extends to resource allocation as well. If a technician calls in sick or gets pulled away for emergency work, supervisors can quickly redistribute their assigned tasks among available team members. The visual nature of the board makes it easy to see which technicians have capacity for additional work and which are already fully committed.

Integration With Existing Maintenance Processes

Most maintenance departments have established procedures for generating work orders, ordering parts, and documenting completion. Effective scheduling tools should enhance these existing processes rather than requiring a complete overhaul of the workflow. Magnetic dry-erase boards integrate well with various maintenance management approaches because they serve as central coordination points rather than replacements for existing systems.

Teams can use the board to display work orders generated from computerized maintenance management systems, translating digital information into visual format for easier coordination. Custom dry-erase board configurations can accommodate specific departmental needs, incorporating sections for parts tracking, technician assignments, completion verification, or safety considerations.

The boards also support hybrid approaches, where some information remains digital, and scheduling coordination becomes visual. For example, detailed work instructions and parts lists might stay in digital format while task scheduling and resource allocation happen on the board. This allows departments to maintain their preferred documentation systems while gaining the coordination benefits of visual scheduling.

Enhancing Team Communication

Clear communication prevents many maintenance scheduling problems. When technicians understand their assignments, supervisors can track progress effectively, team members coordinate efficiently around shared resources, and maintenance operations run more smoothly. Magnetic dry-erase boards contribute to improved communication by providing a central information source that requires no special access or training to interpret.

Team meetings are more productive when participants can reference a shared visual representation of upcoming work. Supervisors can point to areas of the board when discussing priorities or resource allocation. Technicians can see how their individual assignments fit into broader departmental objectives. This shared visual reference helps reduce misunderstandings and ensures everyone operates with consistent information.

The boards also facilitate communication between shifts. Day shift personnel can leave notes about incomplete work or changing priorities that night shift workers can see immediately upon arrival. This continuity helps maintain scheduling momentum across different work periods and reduces the coordination gaps that often occur during shift changes.

Scheduling maintenance with magnetic dry-erase boards represents a practical solution for departments seeking to improve their coordination effectiveness without abandoning proven processes. These boards provide the visual clarity necessary for making complex scheduling decisions while maintaining the flexibility required for dynamic maintenance environments.

Implementing Your Scheduling Solution

The transition to scheduling maintenance with magnetic dry-erase boards requires thoughtful planning to maximize effectiveness. Consider your department’s needs when designing board layouts and establishing procedures for updates and maintenance. Involve team members in the planning process to ensure the system addresses real workflow challenges rather than creating additional administrative burden.

Begin with basic scheduling functions, and gradually expand the system as team members become comfortable with the visual approach. This allows departments to refine their procedures based on experience rather than theoretical assumptions about what might work best.

For organizations ready to enhance their maintenance scheduling capabilities, magnetic dry-erase boards provide a reliable foundation for improved coordination and communication. Contact our team to discuss custom dry-erase board options that align with your operational requirements and help your maintenance department achieve greater scheduling effectiveness.