Lean manufacturing is grounded in the principle of continuous improvement and waste reduction. However, manufacturing teams require clear, effective communication tools to implement lean processes that successfully promote organization and collaboration. Printed whiteboards enhance lean manufacturing by offering a practical, visual method to organize workflows, monitor progress, and align team efforts.

This blog will explore how printed whiteboards enhance lean manufacturing through improved visibility, enhanced communication, productivity tracking, and adaptability. By the end, you’ll clearly understand why investing in this tool can be a game changer for your manufacturing processes.

The Role of Visual Tools in Manufacturing

Effective lean manufacturing requires clear communication and collaboration to minimize errors and waste. Visual tools like printed whiteboards play a significant role in creating clarity within the workspace. These tools allow team members to keep track of operations, identify bottlenecks, and maintain focus on their goals.

Different from digital alternatives, printed whiteboards offer immediate and flexible accessibility. They require no technical expertise or electronic devices, making them easy to implement across all levels of your team. Visual management boards emphasize information simplicity through layouts designed to display critical updates.

Customization options also allow businesses to tailor boards to reflect their unique needs, keeping operational nuances visible and manageable. These boards become the centerpiece of any workspace by providing an intuitive visual reference for everyone involved.

Supporting Clear Communication

Clear communication is at the core of every successful lean manufacturing process. Miscommunication often leads to unnecessary delays, quality issues, and increased costs—problems that lean principles aim to eliminate. Printed whiteboards act as tangible, centralized hubs for critical information, ensuring all stakeholders can access the same data in real time.

Printed whiteboards help teams focus on shared goals by prominently displaying schedules, performance metrics, and improvement projects. For example, a board tailored for production tracking ensures that workers across different shifts always stay on the same page. The visual nature of these boards prevents misunderstandings and eliminates the need for extensive explanations or repeated clarifications.

Teams that use printed whiteboards for daily huddles or meetings notice increased alignment in their objectives. Important updates are visible to everyone, fostering greater accountability and ownership. Collaboration improves significantly when everyone knows where they stand and what’s needed.

Enhancing Productivity Through Accountability

Printed whiteboards are powerful tools for improving productivity. They allow teams to easily track tasks and measure performance progress. Simplified layouts and bold visuals keep data consistent and accessible, encouraging quick actions to resolve inefficiencies.

Imagine a whiteboard designed to track key performance indicators (KPIs) in real time. These metrics could include production output, downtime, and defect rates. Continuously monitoring this information enables teams to address roadblocks immediately, reducing downtime and maintaining workflow momentum.

Printed whiteboards also inspire a culture of accountability. Team members are naturally motivated to achieve their targets when performance metrics and assigned tasks are clearly displayed. Transparency within the workplace creates an environment where everyone strives to improve individual and collective outcomes.

Supporting Lean Inventory Management

Inventory management is another critical aspect of lean manufacturing that benefits from printed whiteboards. Instead of relying on complex software or spreadsheets, individuals can use whiteboards, which provide an intuitive solution to visually organize inventory-related data.

Teams can easily monitor stock levels, reorder schedules, and supply chain statuses, reducing the risk of excess inventory and stockouts. Gaining an understanding of inventory trends ensures teams can make adjustments proactively and avoid unnecessary waste. Whiteboards tailored to Kanban methodology, which emphasizes efficient inventory replenishment, can further streamline material handling processes.

Custom printing options allow businesses to develop boards that align perfectly with their unique material flow systems. This ensures that inventory data is managed effectively and presented in a clear and actionable format for everyone in the production chain.

Supporting Continuous Improvement in Lean Manufacturing

Continuous improvement is central to lean manufacturing, and printed whiteboards are essential for driving these initiatives. Printed whiteboards encourage teams to identify and solve issues collaboratively by making data readily visible and easy to interpret.

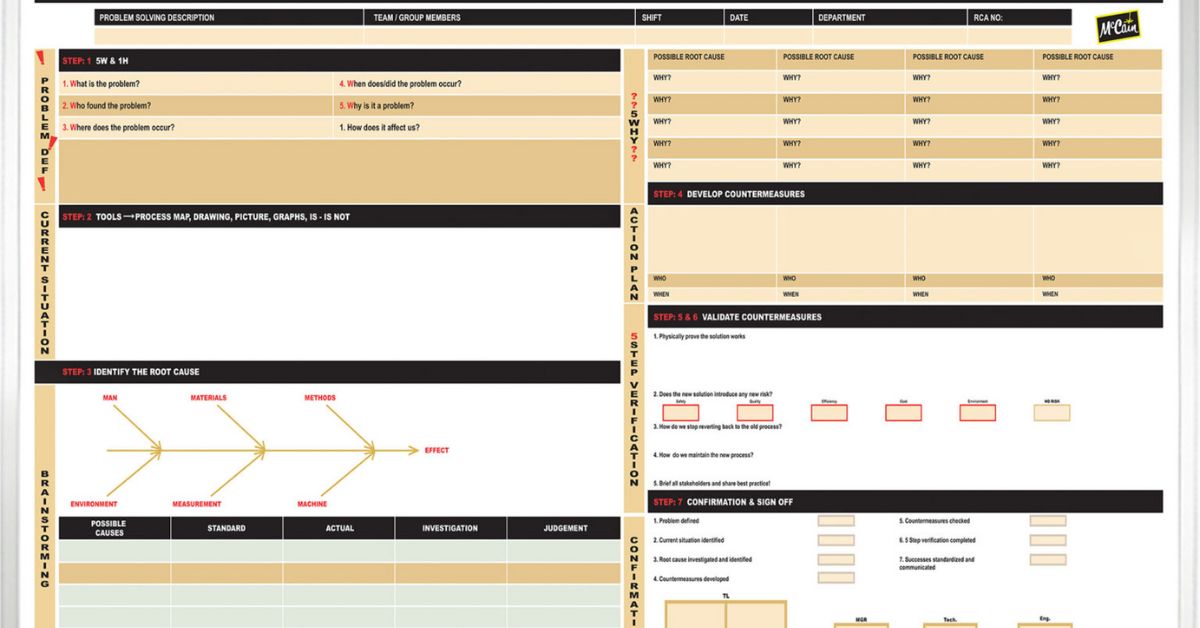

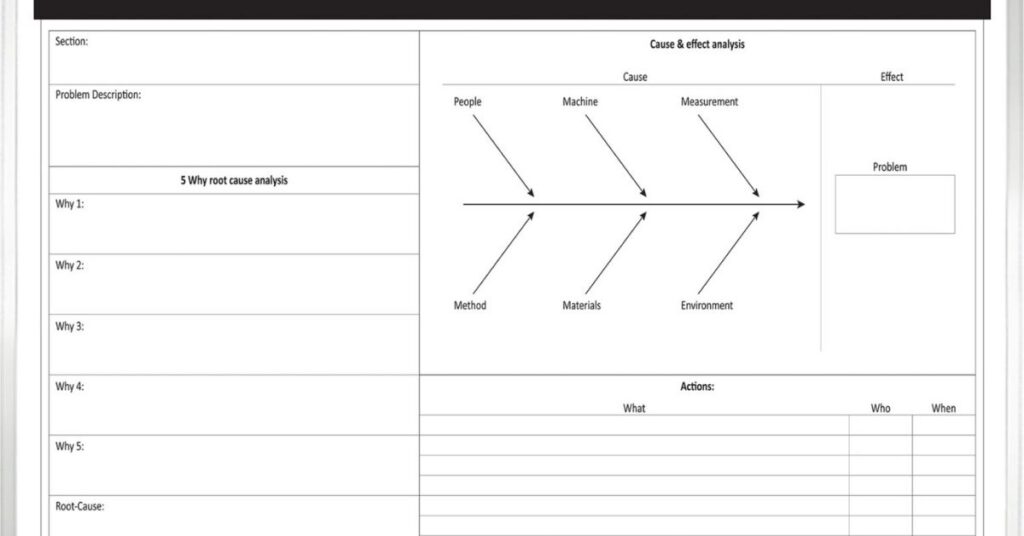

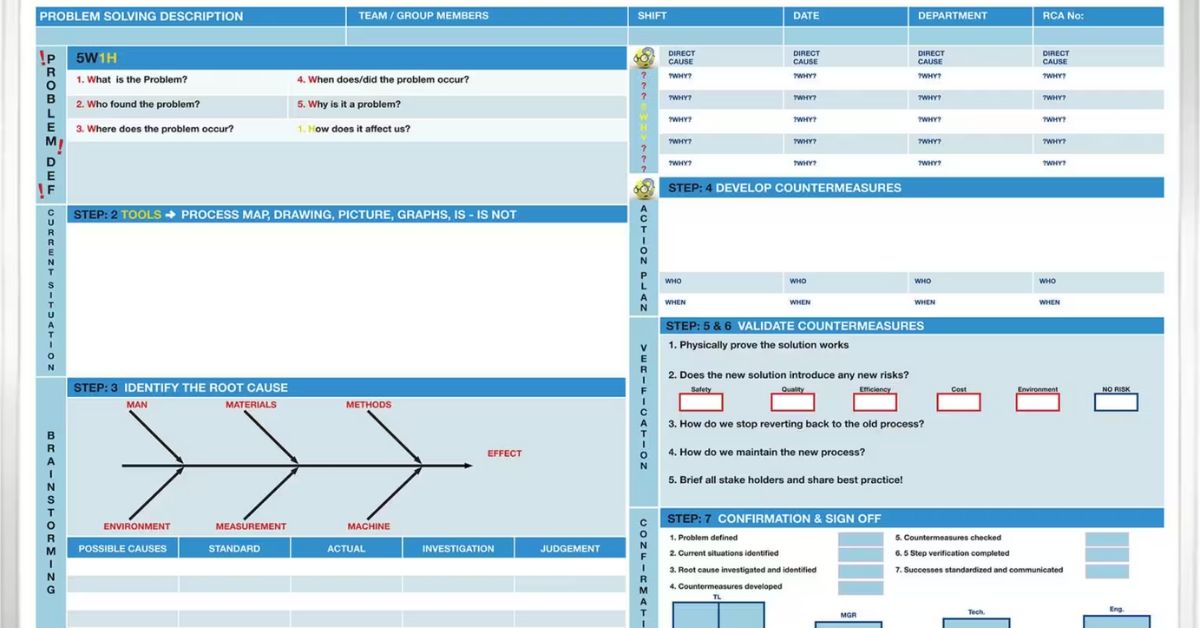

For example, problem-tracking boards support lean principles by helping teams document recurring issues. These boards provide space to record problem descriptions, root causes, and assigned resolutions. Regularly updating this information keeps everyone focused on addressing inefficiencies and implementing sustainable improvements.

Additionally, boards featuring timelines or action plans help prioritize improvement projects. Teams can break down significant goals into manageable steps, ensuring consistent and tangible progress. Visualizing key milestones fosters greater accountability and keeps the focus on achieving measurable results.

Adapting to Evolving Needs

Printed whiteboards offer manufacturers the adaptability needed to respond effectively to evolving demands. Unlike software tools that are bound to static layouts or templates, whiteboards can be customized to reflect changing priorities, capacity adjustments, or process evolution. For example, an assembly line undergoing reconfiguration could benefit from printed production boards that align with updated workflows.

Customization ensures that printed whiteboards seamlessly integrate with diverse operational needs across departments. This adaptability makes them a highly versatile and reliable tool in adhering to lean manufacturing principles, even as businesses grow or pivot their strategies.

Why Printed Whiteboards Are a Long-Term Investment

Investing in printed whiteboards benefits lean manufacturers for the long term. Their low-cost implementation and durability make them accessible tools for businesses of all sizes. Unlike disposable alternatives or software applications with ongoing fees, whiteboards with printed designs offer a one-time up-front expense that delivers extended value over time.

Additionally, customization options amplify the value of whiteboards. Boards can be tailored for specific applications, from monitoring safety protocols to tracking preventive maintenance schedules. This ensures that your initial investment is practical and directly aligned with your company’s needs.

By committing to printed whiteboard systems, manufacturers create an environment optimized for communication, transparency, and continuous improvement—all key pillars in sustaining lean manufacturing principles.

Transform Your Lean Manufacturing Strategy Today

Implementing printed whiteboards enhances lean manufacturing practices by fostering clear communication, improving accountability, and providing the adaptability you need in a continuously evolving industry. These tools align directly with lean principles, offering unmatched versatility and accessibility for teams striving for operational excellence.

If you’re ready to elevate your manufacturing processes and maximize efficiency, our team is here to help. At MagiboardsUSA, we specialize in customizing solutions that are tailored to your needs. Contact us today to explore how our expertly designed printed whiteboards can drive your lean initiatives forward.